Our Technology

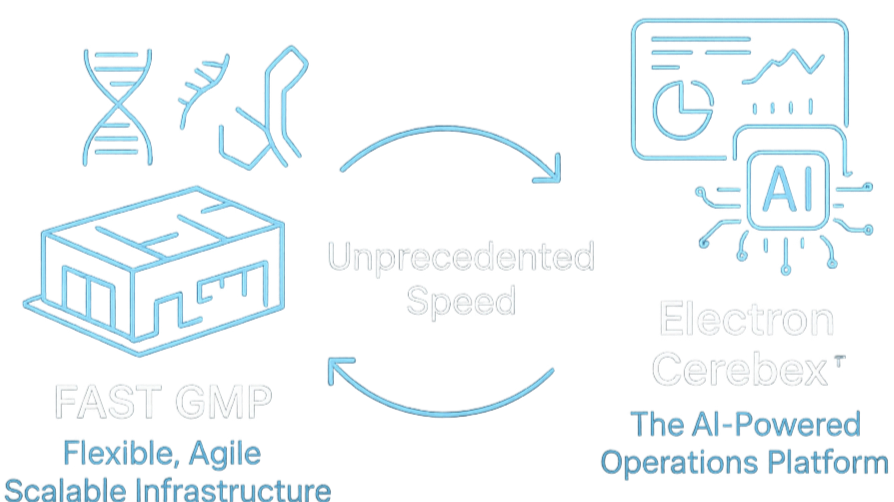

Part of our competitive advantage is built on two interconnected core innovations: a revolutionary approach to physical infrastructure and a unifying layer of artificial intelligence. Together, they create a manufacturing capability that is faster, more flexible, and more intelligent than any traditional model.

FAST GMP™: Flexible, Agile, Scalable Infrastructure

The traditional, stick-built GMP facility is a primary source of cost and delay. Our FAST GMP™ model re-engineers the physical plant by leveraging modular, reconfigurable cleanroom "pods" within flexible warehouse-like shell spaces. This "ballroom" concept, built on closed systems, allows for the segregated, parallel production of multiple products while minimizing the need for large, costly cleanroom environments.

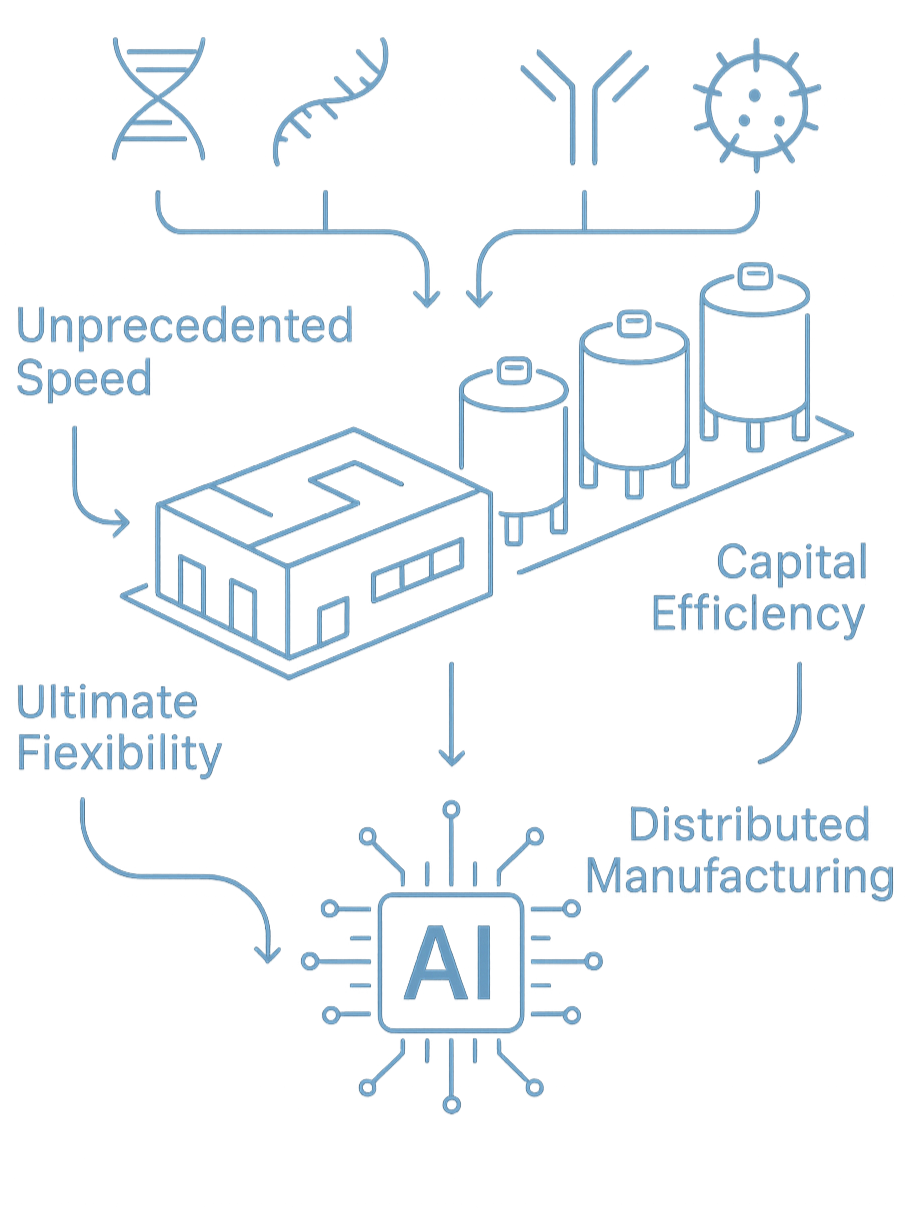

Key Benefits:

Unprecedented Speed: Become operational quickly — Targeting at least 50% reduce lead time compared with traditional approaches.

Radical Capital Efficiency: Radically reduced facility costs

Ultimate Flexibility: Rapidly scale, pivot, and reconfigure for new modalities, including RNA, DNA, Protein, cell-based, and viral products.

Facilitates Distributed Manufacturing: Utilizing standard fast to deploy systems

Electron Cerebex™: The AI-Powered Operations Platform

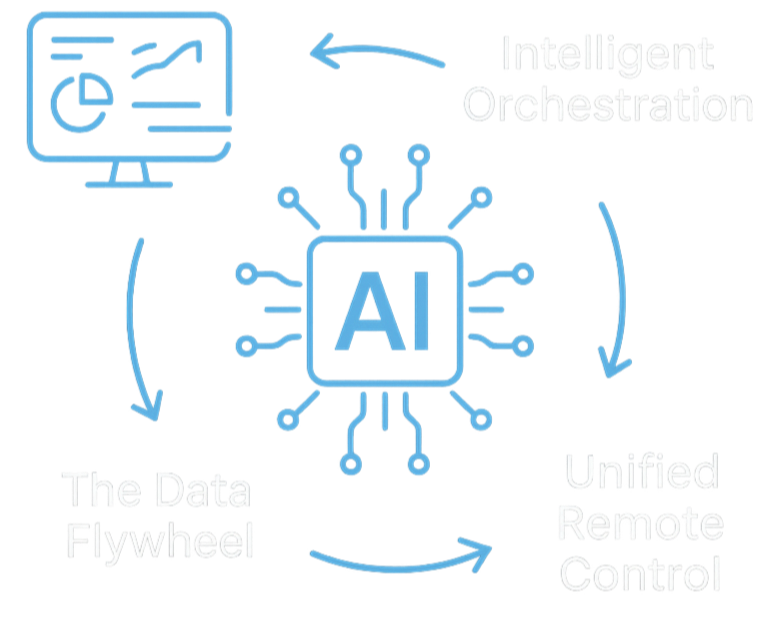

A distributed network is only as powerful as the intelligence that connects it. We are building Electron Cerebex™ an AI Overlay—the GxP-compliant "digital brain" that serves as the central nervous system for our manufacturing ecosystem. It solves the "profound operational drag" that forces skilled professionals into roles as "manual data integrators" by providing a universal interface to unify and orchestrate disparate systems like MES and LIMS.

Key Features:

Intelligent Orchestration: A "digital workforce" of specialized AI Agents provides real-time process optimization, quality verification, and predictive insights.

Unified Remote Control: A single, compliant interface enables remote operation, monitoring, and control of all systems across distributed manufacturing sites.

The Data Flywheel: Every batch and process run feeds the platform, creating a "virtuous cycle" of continuous learning that over time makes the entire network smarter and more efficient.